Ink

It’s complex chemistry

The science of ink formulation is one of the most significant, if not the most significant, factors driving the current inkjet revolution. Ink is complex chemistry. It’s colorants (dye or pigment varying in type and density), resins (protecting colorants and reduce metamerism), mediums (suspending the colorants), solvents (increasing viscosity to deliver it through tiny nozzles), and drying agents (decreasing drying time and reducing dot gain).

Consider the currently reigning inkset for professional photographic inkjet printing – Epson’s UltraChrome HDR. Epson UltraChrome HDR ink’s exceptional pigment density delivers supersaturated colors and dense blacks unprecedented in photographic output, able to be delivered in small droplet sizes (2-6 picoliters – a picoliter is one billionth of a billionth of a liter), smaller than the width of a human hair, so quick drying that droplets form a precise dot and prints emerge from printers essentially dry, water and ozone resistant pigment is encapsulated to reduce light refraction and abrasion. High Gloss Microcrystal Encapsulation Technology is formulated into the inkset’s suspension technology to make the print surface more uniformly reflective despite dramatic variances in ink density throughout a print. While counteracting the tendency for gloss to reduce as pigment content increases, gloss-optimizing additives also increase translucency allowing higher ink density and chroma.

Epson still leads the inkjet revolution. Recently, there are competitors whose newest solutions and their immanent evolutions deserve serious consideration and monitoring – Canon’s Lucia inkset and HP’s Vivera inkset.

Epson K3 on matte and luster

Dye vs pigment

While there are profound differences between dye-based and pigmented inks, the differences in image quality are frequently overstated and sometimes misstated. Years ago, pigmented inks suffered from reduced gamut (saturation) and dmax (maximum density or black) and increased metamerism. Today the differences lie largely in the areas of longevity and durability, where pigment still reigns supreme. (Cost may also be impacted, as dye inks are typically less expensive to manufacture.)

Multiple inks

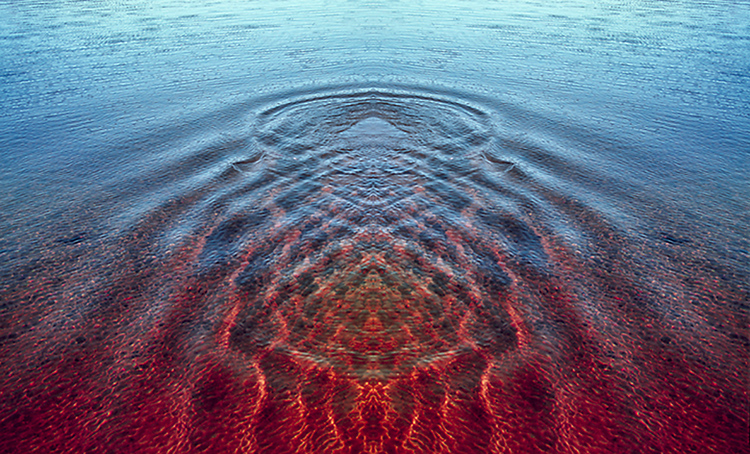

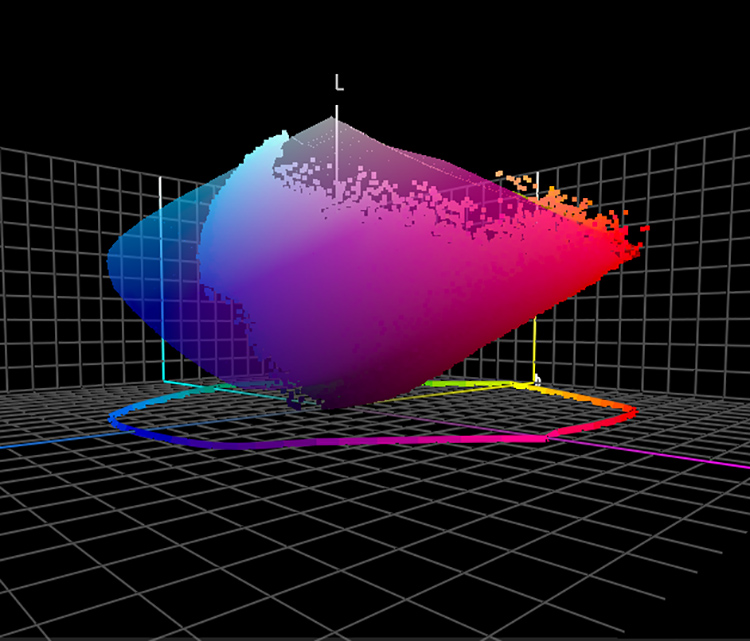

To improve gamut and dmax manufacturers have been adding more inks to inksets; alternate colors (variants of offset’s high-fi orange and green, light cyan and magenta, or red, green, and blue) and additional blacks (blacks optimized for matte and glossy surfaces, light and medium blacks or grays) are used in combination with CMYK.

Do more inks yield better image quality? Typically. But not necessarily. Image quality is the result of a combination of a number of factors. To assess print quality, you have to assess the total printing solution – ink, profile, rendering intent, driver, screening algorithm, ink limit and substrate. Compare gamut, dmax, ISO brightness, neutrality, graybalance, metamerism, gloss differential, bronzing, gradation, fine line detail, longevity and durability. Both the physical makeup of ink and its application are important.

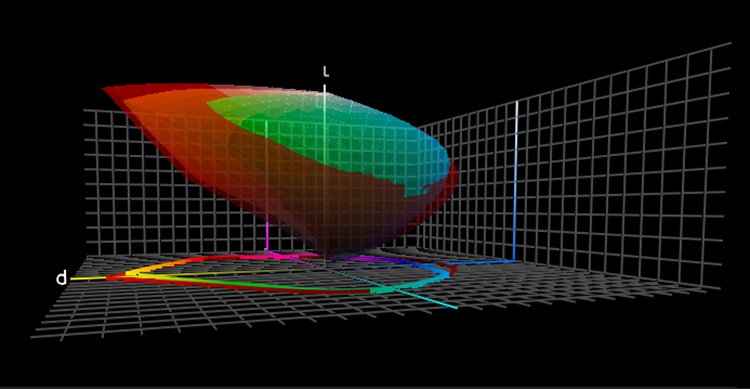

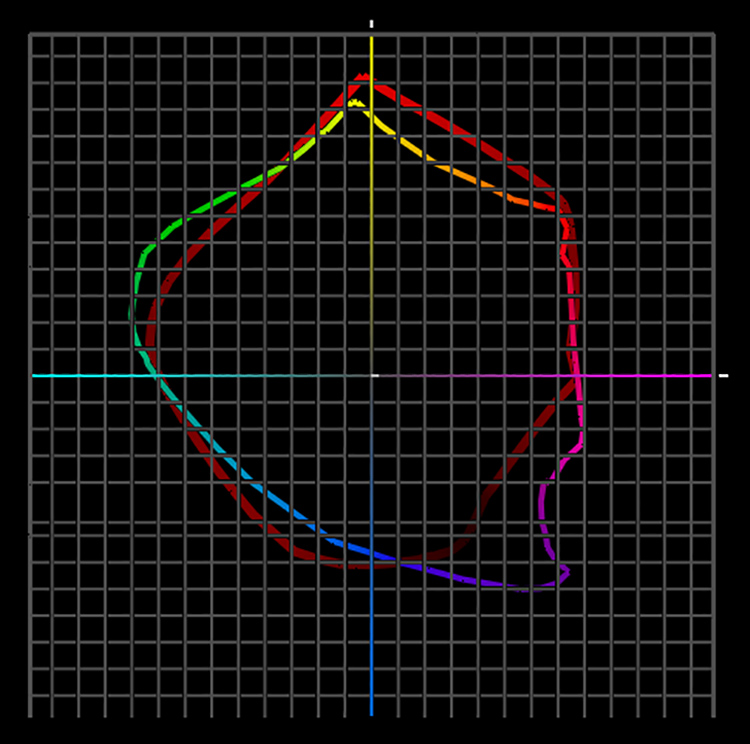

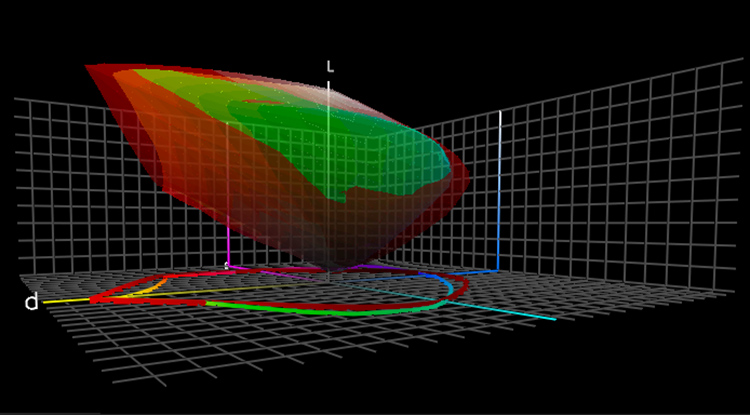

Gamut and dmax

The impacts of increased gamut and dmax are both easily seen. Gamut has a dramatic impact on color but not black-and-white print quality – more saturated color. Dmax has a tremendous impact on both color and black-and-white print quality – blacker blacks.

What is not obvious is that greater dmax extends gamut by increasing the saturation of dark colors.

Dmax and gamut figures for inkjet prints are at a photographic all time high. Both significantly exceed traditional print materials. (Dmax – silver gelatin 2.35, Epson UltraChrome HDR 2.45, Canon 2.5.)

Neutrality and graybalance

Inksets with multiple black inks not only deliver the best dmax, they also deliver the best neutrality and graybalance (consistent tint throughout the tonal scale). Producing truly neutral and consistently neutral colors with supersaturated inks is quite challenging; black ink becomes a stabilizing factor. While ink is an essential factor, it is not the only factor – driver’s and profiles play a significant role.

Highlight detail

Light inks, including light black inks, aid in the reproduction of highlight detail. They hold detail with not just smaller but also less visible dots.

Metamerism

Metamerism can be reduced with multiple black inks and heavier black plate generations (using more black ink to reproduce the image). Metamerism can be minimized by reducing the use more metameric saturated inks and increasing the use of less metameric neutral inks. Metamerism can also be subdued by coating irregularly shaped pigment particles with polymers, making surfaces more uniform and reducing light refraction.

Gloss differential

Gloss differential is an uneven sheen due to varying ink densities in highlights and shadows that affects glossy surfaces significantly more than matte surfaces. Gloss optimizing additives are incorporated into ink formulation to dramatically reduce gloss differential. It goes where ink doesn’t. It also counteracts the tendency for gloss to reduce as pigment content increases. It goes where ink doesn’t.

Sprays, coatings, and varnishes applied after printing can also help reduce gloss differential. When using these types of non-native chemistry guard against staining and poor adherence, the tendency towards additive failure (reduction of gloss, dmax, or gamut), and possible reductions of longevity. (Download a free PDF review of PremierArt’s PrintShield sprays at www.johnpaulcaponigro.com.)

Bronzing

Inkjet prints may display bronzing (an iridescent flash of colors seen at different viewing angles particularly noticeable in neutral areas). Heavier black plate generation and alternate screening frequencies (dot placement) dramatically reduce this.

Longevity

Dye ink achieves significant lightfastness and ozone resistance only with a limited choice of swellable papers, which are not water-resistant and prone to running in high levels of humidity. (Epson’s new Claria ink is an exception whose longevity ratings approach 100 years on a wide variety of substrates.) Pigmented ink offers superior longevity and durability with lightfastness, water and humidity resistance, and ozone resistance on all media (swellable, porous, rag). Inkjet longevity ratings are reaching new highs in photography (for color108 years, 166 years with PremierArt Spray – for black-and-white 284 years and 312 years with PremierArt Spray). (See wilhelm-research.com for more information.) Longevity is derived from a complex set of factors chemistry, adherence, lightfastness, and exposure are a few of the key elements. Where longevity is a concern, use tested materials whenever possible.

Durability

Durability can be seen as separate from longevity or an extension of it. Ink plays a role. Pigmented inks are prone to scuffing and burnishing. Sprays can reduce this tendency somewhat. Related issues such as scratching, cracking, flaking involve ink but are often more attributable to substrate. Handle with care.

Switching inksets

Choosing an inkset limits or determines your choice of printer model. While some printer models can accommodate more than one inkset (generally not simultaneously), printers are usually designed for a specific inkset.

Avoid switching inksets in the same printer, such as dye with pigmented or the printer manufacturer’s inkset with a third-party manufacturer’s inkset. Don’t confuse this with swapping inks within the same inkset, such as different ink cartridges of the same ink or different black inks designed for specific substrates, such as matte and glossy. Different inksets inevitably contaminate one another producing unreliable results and frequent clogging. If you do switch inksets, be sure to thoroughly flush a printer of all residual ink before installing a new ink type.

Epson K3 verus Canon Lucia

Third party inks

There are a number of third-party manufacturers who produce both dye-based and pigment-based inks – Lyson, MIS, Generations, ConeTech, etc. It’s nice to have a choice. Many users are happy with them. While these inksets often offer significant savings over the printer manufacturer’s inksets, I’ve never been as impressed with the quality they deliver. Third-party inks are prone to clogging. Longevity is often questionable. Using them sometimes voids the warranty on your printer. Buyer beware.

The bottom line

While it is only one factor you should consider when evaluating print quality, ink is of paramount importance. Choosing an inkset is one of the most important decisions you can make when selecting tools and materials to make fine prints with. Research your options thoroughly and explore all the related variables carefully before committing your images to print. Continue monitoring this rapidly evolving field. Its arc has been so stunning that in less than a decade, inkjet printing has changed the nature of the photographic print.

Read more on digital Printing here.

Learn more in my digital photography and digital printing workshops.